DHSEAWORKS

TSHD Swalinge

Familiar and good

"The Swalinge"

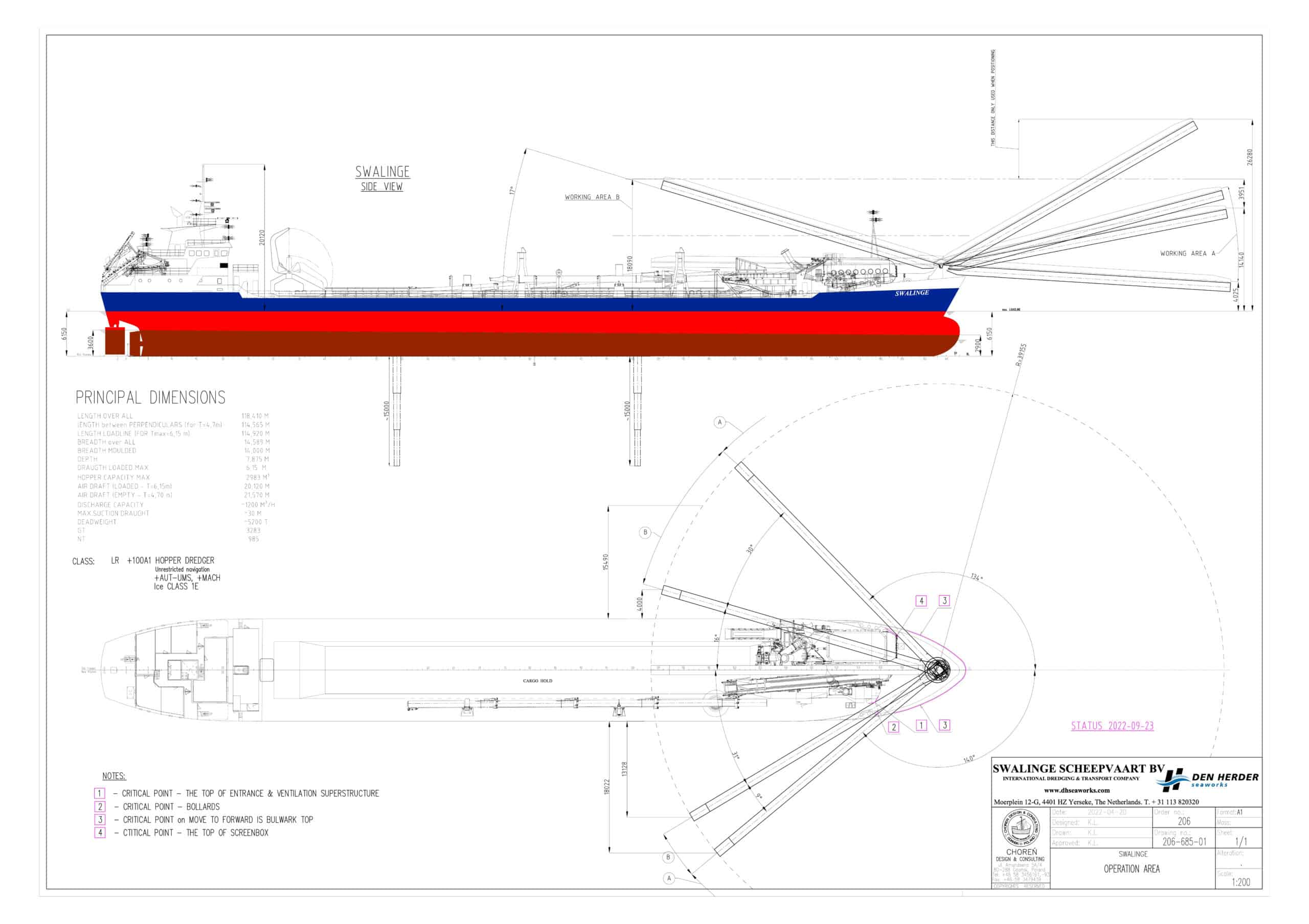

The Swalinge was built as a coaster in 1977 and rebuilt into a trailing-suction hopper dredger after being purchased by Den Herder Seaworks in 1996.

The extension of the Swalinge with 37.1 m is realized in 2022.

The dry-unloading installation with unloading crane, conveyor belts and shore belt have been developed and built according to our own insights. The unloading time of the Swalinge will be around 2.5 hours.

The hopper of the Swalinge is fitted with bottom doors so she can dump her cargo. She is also capable to use a shore delivery installation for pumping the cargo ashore.

Extension and modernization of the TSHD Swalinge

By the modernization and extension of the Swalinge arises an improvement of her capabilities within our fleet and can transport-movements/deliveries better be coordinated and optimized.

The main components of the conversion of the TSHD Swalinge are:

- Extension by 37.1 m, increasing the loading capacity by 1200 m3 to approx. 3000 m3.

- Installation of two extendable spud poles to shorten mooring and mooring times.

- The construction and design of a completely new hydraulically adjustable sieving installation.

- Fitting a second 450 kW bow thruster for better maneuverability.

- Fitting a nozzle around the propeller.

- Installing a newly designed bulbous bow.

- Renewing messroom, kitchen and accommodation for the officers.

- Modernization and renewing of the communication equipment.

- Installation of a free-fall boat.

Video

Specification

Photos

Type of vessel:

Single screw trailing suction hopper dredger with nozzle, single suction pipe, bottom doors, shore press and dry unloading installation with crane, conveyor belts and shore belt.

1977/ converted in 1996 and 2022

spud poles

2x telescopic, winch operated.

Dimensions:

Tank capacity:

Dredger installation:

Hydraulic crane with grab of 13m3, mobile on rails, conveyor belts and shore belt electrically/hydraulically driven